End diaphragms in the steel box girder

.

.

.

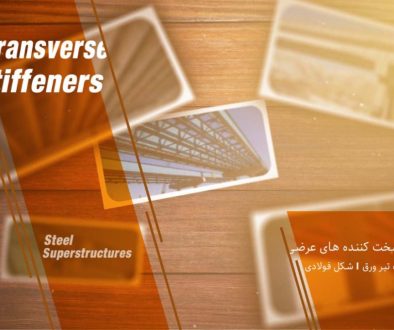

U-shaped steel girders (tub girders) composite with a hardened concrete deck form a closed- box, torsionally strong bridge system. A typical cross section of a twin tub girder system is shown in Figure 1.

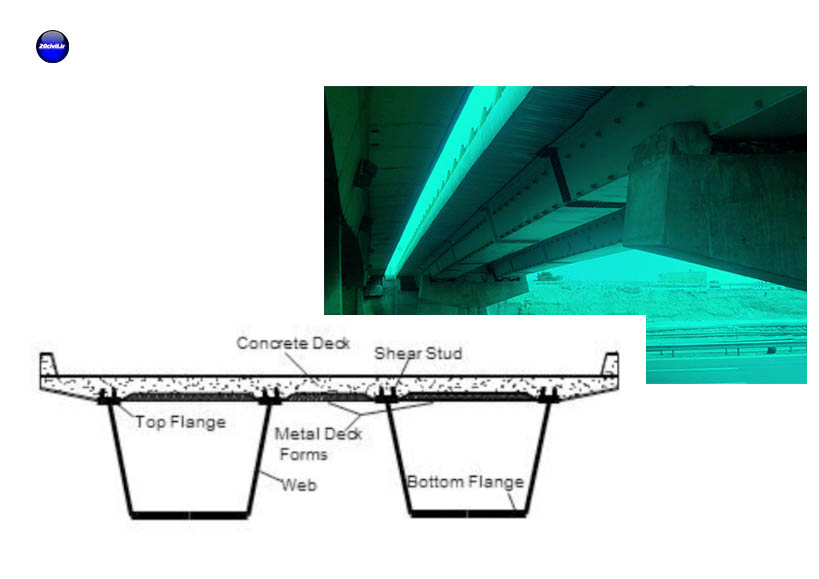

Similar to I-girder bridges, the steel end diaphragms (internal and external) in the tub girder bridges are responsible for transferring the superstructure lateral loads, such as seismic loads, to the substructure using shear action.

According AASHTO (2011) guide specification for LRFD seismic bridge design introduces three different strategies for seismic design in bridges

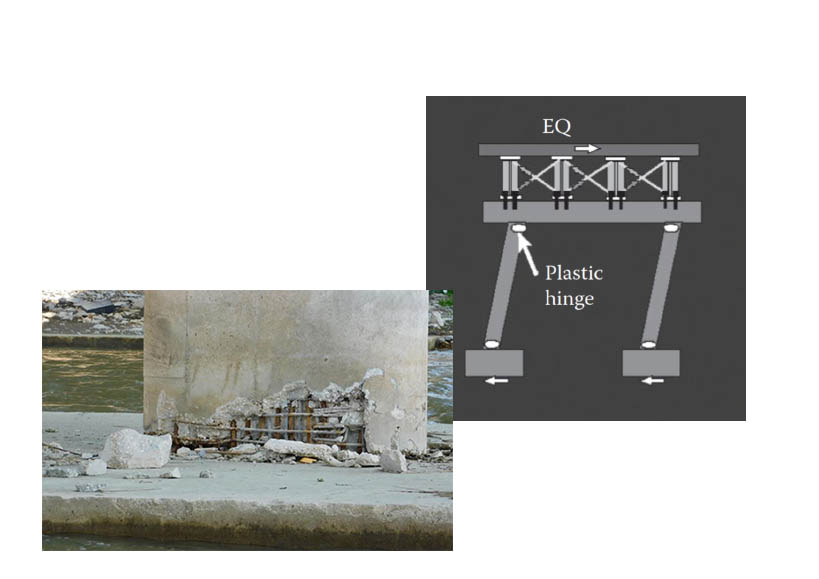

The first strategy or conventional design procedure is substructure piers and abutments in order to mitigate the seismic demand. Accordingly, significant damage to these concrete elements is expected in strong earthquakes

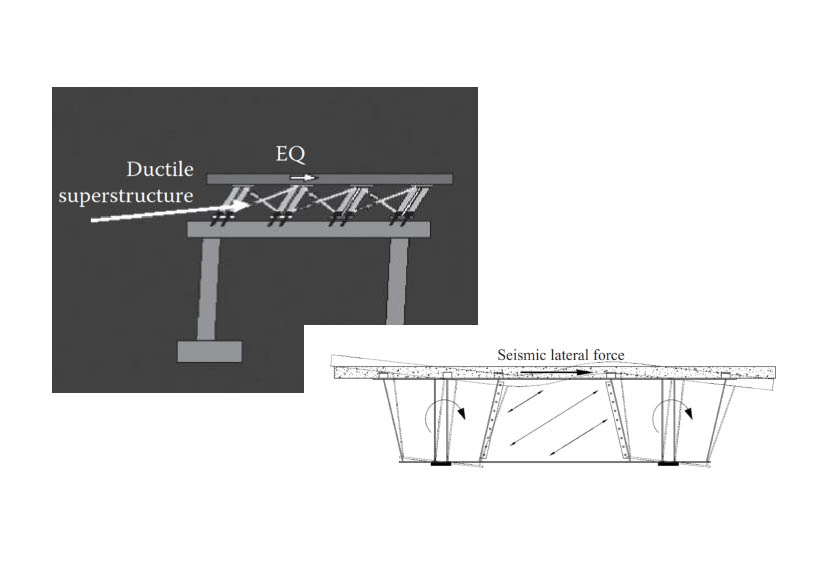

The second strategy uses ductile elements of the superstructure to absorb the seismic demand

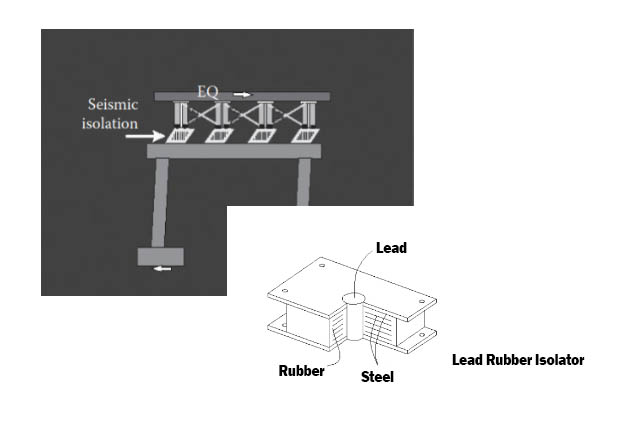

The third strategy employs damping devices installed between the superstructure and substructure to act as fuse elements. There are valid concerns about the cost of damping devices such as lead rubber bearings (LRB) and high damping rubber bearings (HDRB) and also the difficulty in fabrication of metallic damping devices in implementing this strategy.

Recently, significant research has been conducted on the second strategy in order to use the existing superstructure bridge components as seismic force reducing systems

Based on investigation the shear behavior of steel diaphragms makes them ideal for seismic energy dissipation and reducing the imposed seismic demands. The transfer of lateral seismic loads to the substructure is achieved through the end diaphragms. These diaphragms are made from steel plates and are connected to the tub girders on each side. Due to the trapezoidal shape of tub girders, both internal and external diaphragms are trapezoidal. The internal end diaphragm is also responsible for vertical load bearing and consequently is better to remain elastic. In this regard, an external end diaphragm was chosen for ductile behavior under seismic action.

.

Reference:

Shervin Maleki and Abouzar Dolati “Ductile steel plate external end diaphragms for steel tub girder straight highway bridges” Earthq Eng & Eng Vib (2020) 19: 759-777